Laser Welding in the Jewelry Industry

Categories

Jewelry Making & Repair

Laser technology has revolutionized the jewelry industry. Unlike traditional soldering, jewelers can use laser welding jewelers to efficiently and effectively repair jewelry without removing heat-sensitive stones and without the use of flux or lead solder. Laser welding is very clean, there is no discoloration and less time is needed to refinish the piece.

Laser welding has been used since the 1970s, primarily in the aerospace and medical industries. In the past ten years, the technology has been adopted by the jewelry industry and has quickly become a must-have tool in the jewelry bench room.

After being adopted to repair jewelry, designers began using the technology on new work, adapting laser welding techniques to create jewelry that is costly or impossible to produce using other methods.

While laser technology has tremendous potential and is an extremely effective tool, the best results are driven by the skills and experience of the jeweler. Understanding the fundamentals of precious metals, jewelry fabrication and gem settings are crucial to understanding when to use a laser welder, when to use more traditional methods and how best to design new work and repair existing pieces.

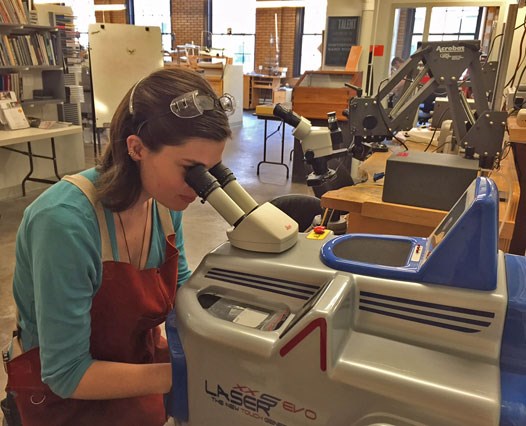

Becoming a proficient bench jeweler take years but learning fundamental skills and techniques in a full-time Jewelry Making & Repair program can jump start a career in the jewelry industry. The program boasts a laser welder, individual benches for each student and instruction in working with precious metals and gemstones. Students graduate from the program with the skills to enter the profession as bench jewelers. Graduates of the program work at top tier jewelry businesses and as award-winning jewelry designers.