The Beautiful Science Behind Violin Making

Categories

Violin Making & RepairThe Violin Making & Repair program at NBSS is a three-year comprehensive curriculum designed to provide our students a solid foundation in the art and science of making stringed instruments. And it is only one of a few such programs in the country. When our students build instruments today, their designs are still based on iconic instruments from the 17th century when exceptional violin construction and patterns were set by the luthiers of the Cremonese era of that time, most notably from the Amati and Stradivari families.

Today, there are still about 500 original instruments built by Stradivari over 300 years ago that continue to create beautiful music in concert halls around the world. And we are still trying to unravel the construction secrets of these incredible instruments.

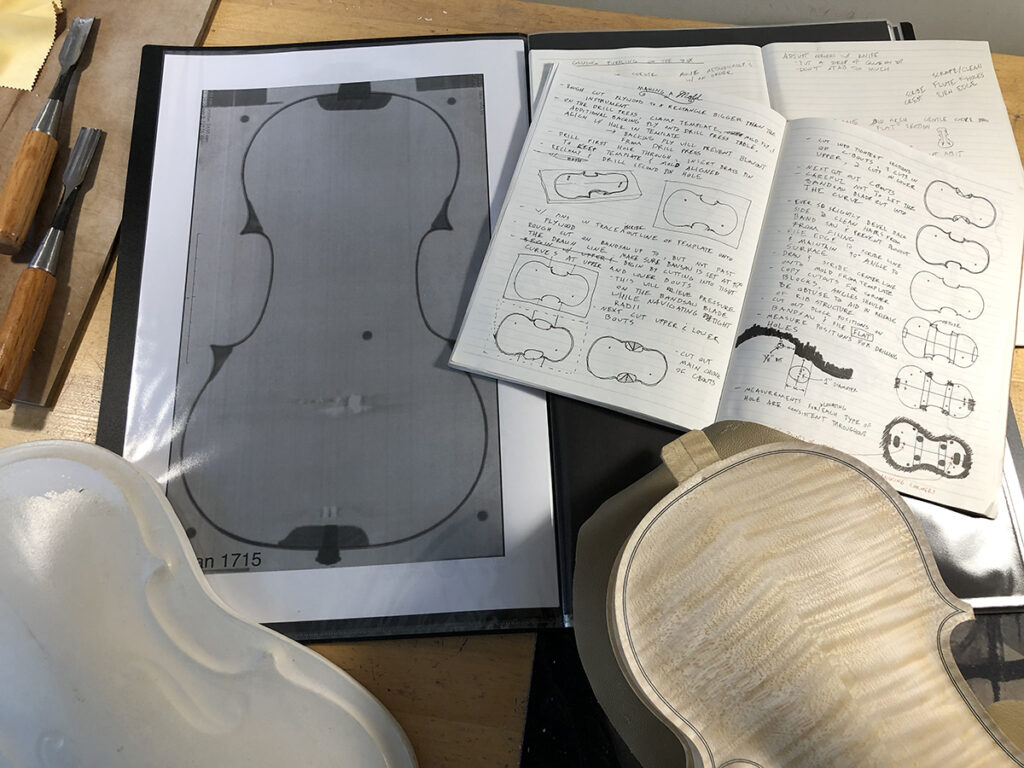

In 2015, violin makers from the Violin Making & Repair program at NBSS partnered with a team of MIT engineers to explore the science of these legendary instruments and their power. Hundreds of violins from the Cremonese-era were meticulously measured resulting in a massive catalog of technical drawings supported by X-ray and CAT scans. The team compared the size and dimension of various features and measured each instrument’s acoustic resonance. In essence their research was plotting the evolution of these instruments over time.

What they found was fascinating. Because of the natural slight variance of one handcrafted instrument from another (about 2%), there was a resulting change in acoustic quality. Over time, these “errors” led to design changes that improved the quality of sound produced. One key finding from that initial research was that the f-shaped openings in the body were a primary factor in the volume and timbre of sound produced—the more elongated the opening, the stronger the sound. The more elongated design also proved to be a more efficient one than earlier, more rounded, designs. Another finding was the significance of the back plate of the violin—thicker back plates more effectively boosted the instrument’s sound.

These improvements weren’t deliberate but happened organically over time. As one article put it: “Through a lot of trial and error, Cremonese masters exploited ‘happy accidents’ and found that an elongated “f” shape for the opening of the resonance chamber and a specific thickness of the back of the violin produced the most pleasant overall sound.”

But these findings are only part of the mystery to discover the secrets of these instruments. More recently, Italian researchers built on these earlier findings to explore the chemical composition of the finishes. What they found was fascinating—a previously unknown protein-based layer applied between the wood and the varnish. And Taiwanese researchers found distinct chemical differences between the maple Stradivari used and that used to create modern instruments. And these are only some of the research efforts that have been devoted to unraveling the secrets of the golden age of violin making.

While it’s exciting to be part of such research efforts and learn more about the science behind creating an exceptional instrument, there is so much more to it. Each luthier puts their own singular mark on their instruments, a remarkable blending of science, design, and the sensibilities of the maker. As Nicholas Makris, the MIT professor of mechanical engineering and acoustics expert who headed those 2015 research efforts with NBSS, put it, “Mystery is good, and there’s magic in violin making. Some makers, I don’t know how they do it—it’s an art form.”

Curious about attending the violin making program at NBSS? Let us know.