Signature Projects: Where Craft Comes into Focus

Categories

Cabinet & Furniture Making, Students, Carpentry, Jewelry Making & Repair, Piano Technology, Preservation CarpentryA behind-the-scenes look at the moments that define NBSS training—from precision milestones to personal breakthroughs.

At North Bennet Street School, the journey from novice to craftsperson is marked not only by skillful repetition, but also by the singular moments when everything just clicks. These “aha” moments—when a tool finally feels like an extension of the hand, when a tolerance is truly understood, or when a student’s confidence shines through a challenging project—are embedded in every program’s curriculum. We asked our faculty: What is one project, lesson, or turning point that defines your program? What stands out as a signature learning experience, both in meaning and in impact?

Their answers offer a behind-the-scenes look at what makes NBSS so unique: a deep commitment to process, precision, and transformation—both of materials and of people.

The Story Stick

Steven O’Shaughnessy PC ’99

Preservation Carpentry, Department Head

One of the real “aha” moments in the PC1 program is the Story Stick. It’s a simple-looking tool, but students knife in razor-fine, precise locations for mortises and tenon shoulders. Up to this point, they’ve relied on drawings, tape measures, and rulers. But the Story Stick represents a shift—building to the edge of a razor rather than to a number on a tape. This mid-year project changes how they think about accuracy, and for many, it’s the moment they really see what precision carpentry is all about.

The Final Bridge Setting

Hillary York PT ’12, PA ’13

Piano Technology (Advanced), Instructor

Late spring is my favorite time in the program. That’s when students work on setting the bridges to their final height—a step that’s critical to a piano’s finished sound. The tolerances are tight, and while the process is intimidating at first, it’s all done with the same hand tools and techniques they’ve been practicing all year. At some point, nearly every student says, “I think I finally understand how sharp a ‘sharp’ chisel really needs to be!” That realization changes everything.

The Chair Requirement

Ellen Kaspern CF ’03

Cabinet & Furniture Making, Instructor

Most people might think it’s the toolbox, but for me, the chair requirement stands out. The way we teach chair making really sets us apart from any other trade or craft school. It’s a huge milestone. Students navigate complex joinery, balance aesthetics with function, and bring a three-dimensional object to life. It requires vision, patience, and an entirely new level of precision—and once they complete it, they’ve crossed into a different realm of skill.

The Hinged Bracelet

Tracey Jenkins Darji JM ’05

Jewelry Making & Repair, Department Head

We don’t have just one “aha” project—our students encounter many turning points across a range of topics. But one recent moment stands out. A student who had struggled through much of the program—often starting projects over—finally hit his stride with one of the most difficult assignments: the hinged bracelet. He was thoughtful, asked questions, and stayed focused. The final product wasn’t perfect, but it showed a level of skill and confidence we hadn’t seen from him before. I insisted he include it in the show. We were so proud. It’s not always that visible with every student, but it’s great when it is.

The Cabinetry Lesson

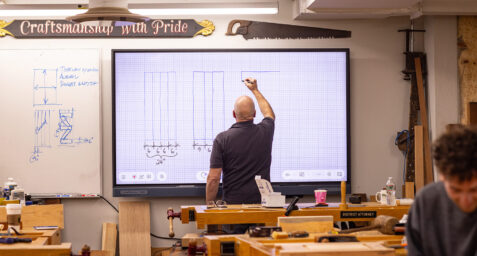

Peter Smith PC ’04 & Brock Leiendecker PC ’16

Carpentry, Department Head & Instructor

Peter: For me, the standout is the Cabinet Making lesson. It’s often a “eureka” moment—some students realize they’ve found what they love in this work. For others, it’s overwhelming—they admire the finished product, but didn’t expect the level of organization, visualization, and endurance it demands. Milling parts for days, holding tight tolerances—it can be energizing or frustrating. But either way, it reveals a lot about who a student is and where they’re headed.

Brock: I totally agree. Cabinetry combines everything we’ve taught up to that point: drafting, framing, trim, milling, architectural details, tolerances, and reading construction plans. Students must visualize the final result and work backwards to execute it—all while solving problems and adapting along the way. It’s a challenge that reveals whether they’re ready for this trade. Even if they never build another set of cabinets, the skills—and mindset—they develop here carry forward into any future they choose.

From chisels to chairs, cabinets to custom tools, these signature projects mark real turning points for our students—where skill, confidence, and craft come into focus. Learn more about our hands-on approach, immersive curricula, and intensive training at nbss.edu/programs.

This story is from our Summer 2025 issue of Benchmarks magazine. Read more stories from the issue or view past issues.